Take full advantage of automation.

Get the most out of your manufacturing business through CJRTec Automated Engineering.

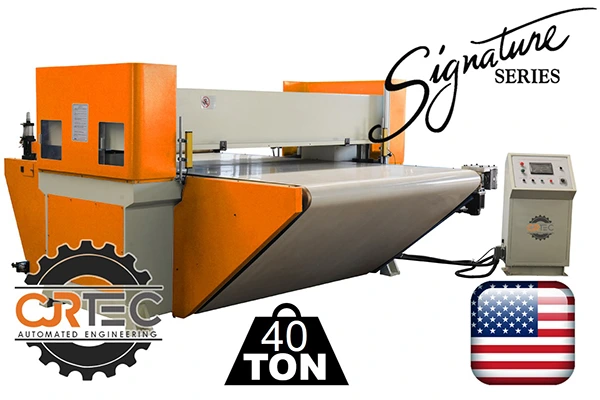

60-DAY BUILD | IN STOCK | |

| Standard | Metric | |

| Max cutting force: | Up to 300 Ton | |

| Video | View Here | |

| Stroke range: | ||

| 30 Ton 63 x 19.5 Cutting Area | $ 53,575.00 | |

| 40 Ton 63 x 19.5 Cutting Area | $ 56,325.00 | |

| 50 Ton 63 x 25 Cutting Area | $ 65,950.00 | |

| 60 Ton 63 x 25 Cutting Area | $ 70,075.00 | |

| 70 Ton 63 x 30 Cutting Area | $ 77,489.00 | |

| 100 Ton 63 x 36 Cutting Area | $ 86,056.00 | |

| 100 Ton 63 x 50 Cutting Area | $ 114,251.00 | |

| 150 Ton 63 x 40 Cutting Area | $ 115,516.00 | |

| 200 Ton 63 x 40 Cutting Area | $ 141,344.00 | |

| 200 Ton 63 x 50 Cutting Area | $ 165,588.00 | |

| 250 Ton 63 x 36 Cutting Area | Call | |

| 250 Ton 63 x 40 Cutting Area | Call | |

| 300 Ton 63 x 40 Cutting Area | Call | |

60-DAY BUILD | IN STOCK | |

| Model Number: | 40-BPC-A-J-N | |

| Standard | Metric | |

| Maximum Cutting Force: | 40 Ton | |

| Cutting Area: | 63.0 | |

| Video | View Here | |

| Operation Manual | ||

| Replacement Parts | Next day shipping | |

| Shipping Cost | Not included | |

| Shipping Responsibility | Buyers | |

| Extended Warranty | Optional | |

60-DAY BUILD | IN STOCK | |

| Model Number: | 50-BPC-A-J-N | |

| Standard | Metric | |

| Maximum Cutting Force: | 50 Ton | |

| Cutting Area: | 63.0 | |

| Video | View Here | |

| Operation Manual | ||

| Replacement Parts | Next day shipping | |

| Shipping Cost | Not included | |

| Shipping Responsibility | Buyers | |

| Extended Warranty | Optional | |

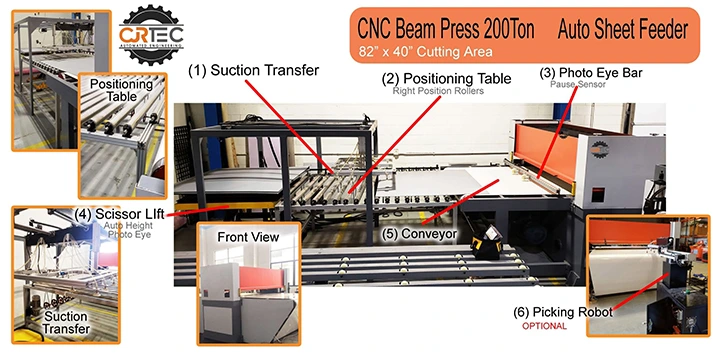

60-DAY BUILD | IN STOCK | |

| Standard | Metric | |

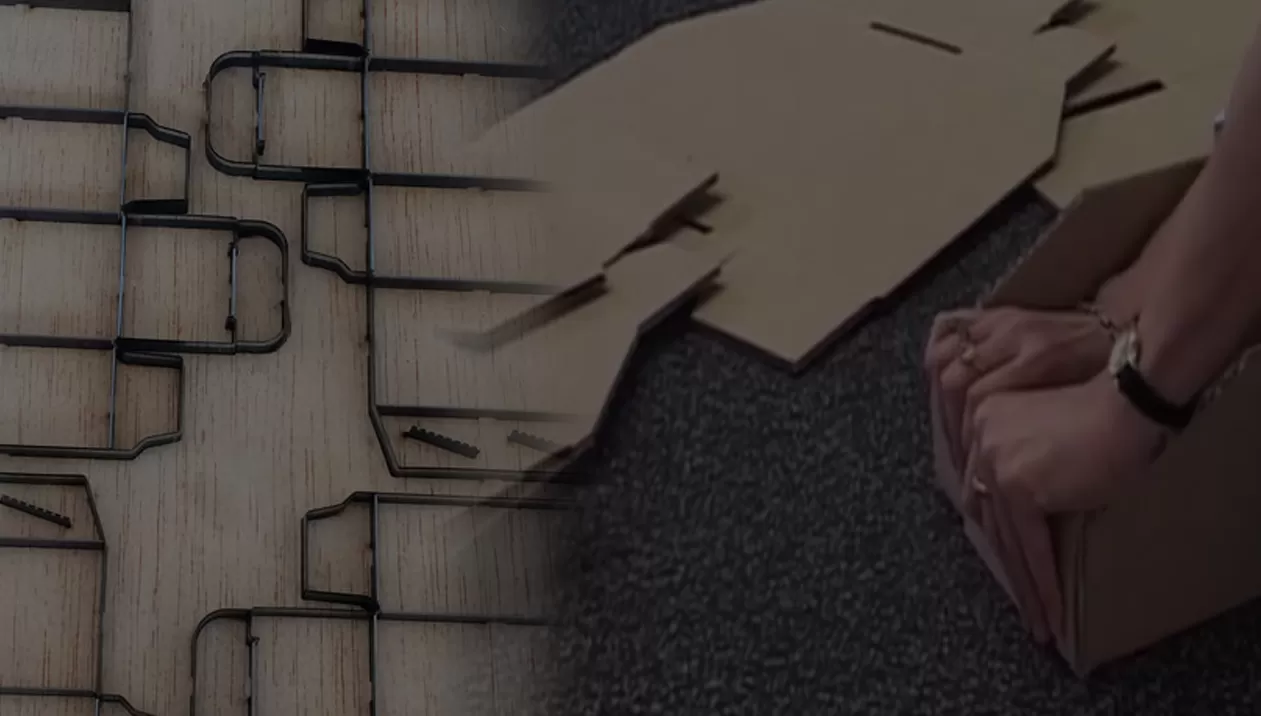

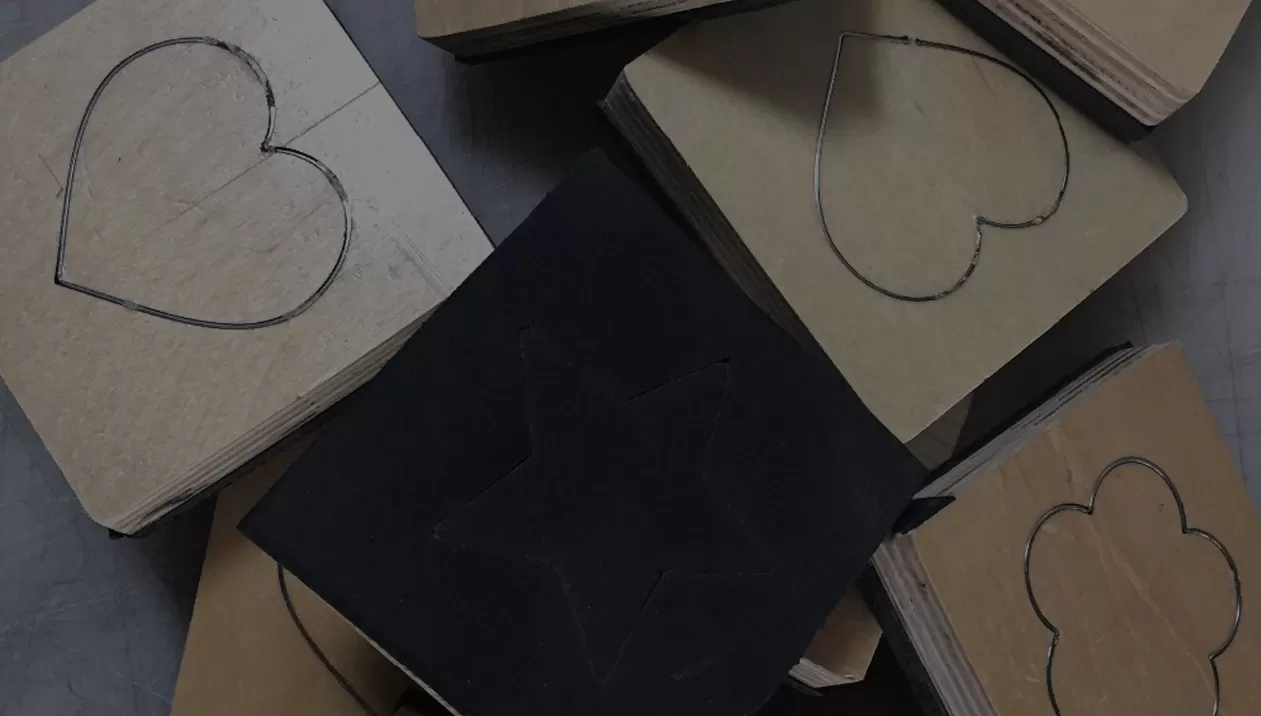

| Custom Built to Cut Flooring | ||

| Max cutting force : | 200 Ton | |

| Stroke range : | 0 | 0 mm |

| Range between the working tables : | 3.0 | 76 mm |

| Size of upper cutting board : | 66.0 | |

| Size of lower worktable : | 66.0 | |

| Motor power : | 20 HP | 27kW |

| Picking equipment size : | 74 x 65 x 67 | 1880 x 1651 x 1702 mm |

| Feeding in table size : | 82 x 67 x 47 | 2083 x 1702 x 1194 mm |

| Machine size : | 147 x 110 x 87 | 3734 x 2794 x 2210 mm |

| Feeding out table size : | 67 x 74 x 47 | 1702 x 1880 x 1194 mm |

| Collecting waste equipment size : | 145 x 31 x 72 | 3683 x 787 x 1829 mm |

| Control box : | 19 x 23 x 51 | 483 x 584 x 1295 mm |

| Auto Sheet Feeder (Stack Capacity) | 400 Sheets | |

| Sheets per hour | 700 | |

| Hydraulic Fluid (Not Included) | ISO 68 | |

| Video | View Here | |

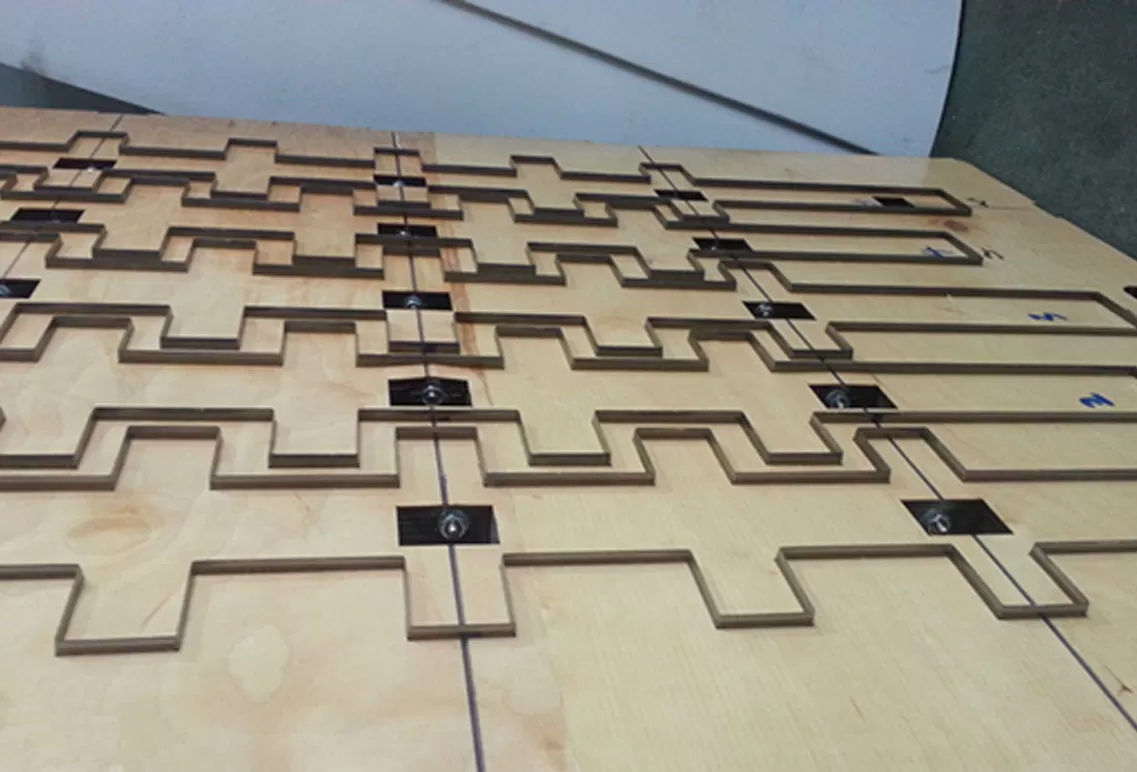

| INCLUDED EQUIPMENT | ||

| * Conveyor Discard system | * Water cooling equipment | |

| * Pneumatic auto sheet feed | * Safety light curtain | |

| * 48 pile sheet lift | * PVC die cut track | |

| * PLC touching screen : Weiview brand | * Laser location system | |

| * PLC: Mitsubishi brand | * Warning working light | |

| * Stop Limitors | ||

60-DAY BUILD | IN STOCK | |

| Model Number: | 200-BPC-A-J-Y | |

| Standard | Metric | |

| Tonnage: | 200 Ton | |

| Stroke: | 0.0 | 0 mm |

| Cutting Area: | 82.0 | |

| Automation: | Gantry Sheet Feeder | |

| Loading: | Auto Scissor Table with Photo Eye | |

| Positioning: | Roller Left Side Positioning Table | |

| Operations: | Auto & Manual | |

| Conveyor Belt: | Continuous Nylon | |

| PLC Controller: | Mitsubishi | |

| Control: | Touch Screen | |

| Cut Control: | Deadmen | |

| Light Curtains: | Front and Back | |

| Auto Picking Head: | Suction | |

| Air Compressor: | Not Included | |

| Vibration Foot Pads: | Included | |

| Die Clamps: | Manual Right Angle Brackets | |

Optional Equipment

| ||