Take full advantage of automation.

Get the most out of your manufacturing business through CJRTec Automated Engineering.

In the manufacturing business, Robotics is a game changing element in restructuring the production process. The most sensible thing to do in this age of computers is to integrate robotic automation to your system in order to have the competitive advantage. Unfortunately, there are several common misconceptions about Robotics that stop companies from doing so, and we’re here to debunk every single one of them.

"Robots are complicated."

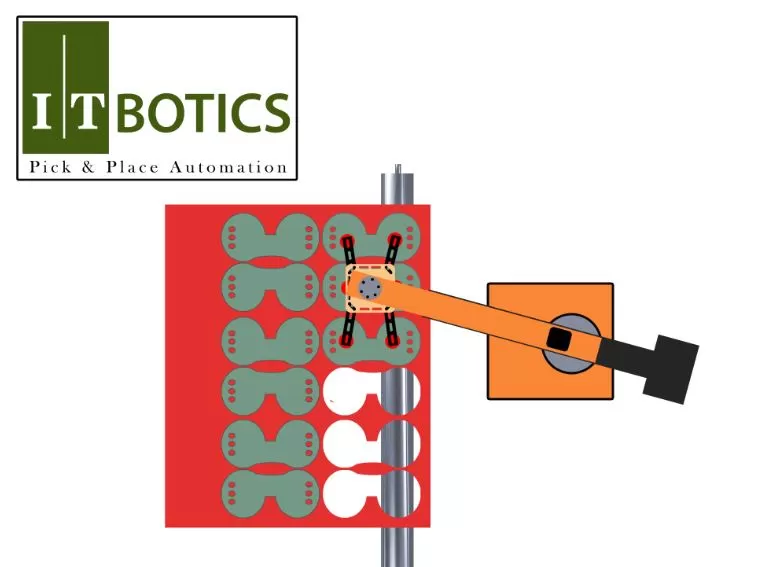

When they hear the word “robot,” people would become skeptical because it is something that we consider as theoretical. Or worse, they think of machines resembling human beings i.e. Transformer when asked what a robot is. By definition, a robot is any automatically operated machine that replaces human effort (source). Nowadays, robots are already being used by most industrial companies in order to automate their business. Admittedly, we used to need an engineer way back then as part of the staff to enter hundreds of codes just to set-up a job. Sounds tedious. But now, there’s no need for an engineer anymore! Our picking robots are integrated with what we call the Drag Technology, wherein you yourself can easily ‘drag’ the robotic arm and put them into position without sacrificing the structural integrity of the machine. Which brings us to the next fallacious thinking about industrial robotics:

"Robots are hard to operate."

As mentioned above, our picking robots are incorporated with the Drag Technology. Operating our robots is as easy as 1-2-3. You can even do it yourself: just “drag”, press “enter”, and then “run.” Simple! Your own secretary can even run it! And to convince you of that, watch our ITbotics videos and see for yourself how easy it is to run our picking robots.

"Robots are expensive."

We admit that it’s logical to think of robots as expensive. People is usually thinking along the range of $100,000 – 200,000 when in fact, these robots are priced between $20,000 – 30,000 only, depending on the functionality that you want it to have. That’s 5x cheaper than you think!

Keep in mind that robots are not like your everyday, consummable products that you buy. Good robots are a form of investment. You pay a huge sum now but in the long run, it will save you as much as a third of your costs.

And if those are not good enough reason for you to buy a picking robot for clicker press, let me ask you this:

"How much do you usually pay for your labor cost?"

We’re going to go ahead and provide you with an estimate. You spend approximately $30,000 – 40,000 a year just for labor cost. You pay people for picking each cut materials up, and for stacking them to another place.

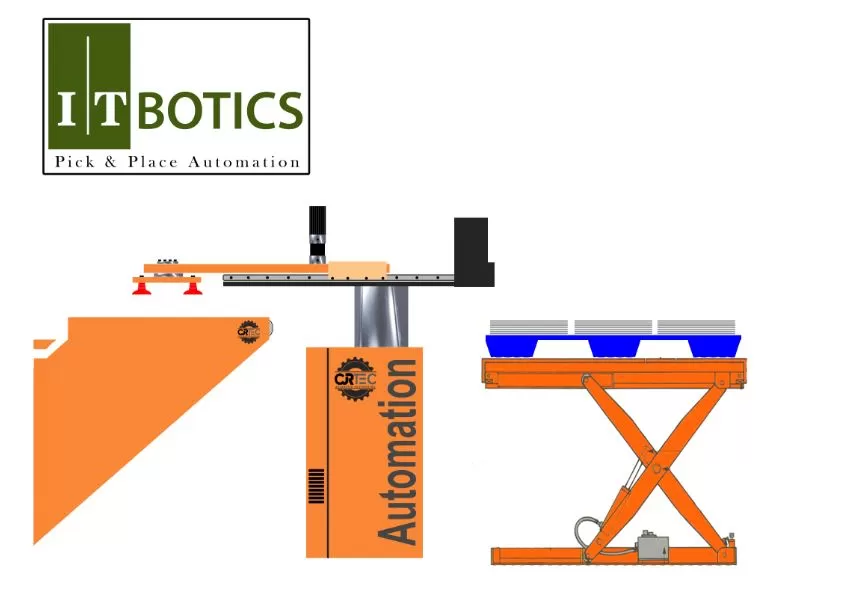

But with our picking robot, it can do that job for you and at the same time, save HUGE amount of money. Once the machines (clicker press and robot) are paid for, say by the end of the year, these machines are basically free afterwards. What’s more, this job can also be achieved 8x faster as compared to manual labor.

Once the clicker press and robot are [both] paid for, these machines are basically free afterward.

You no longer have to rely on a lot of people because robots don’t get sick, pregnant, come in late, or ask for more money.

Everything goes down to “cost per piece” when you’re in the manufacturing industry. Our picking robot can help you significantly lower your cost, in order for you to get higher returns.

If you are now super convinced of the perks of having a picking robot included in your process, take these things into consideration before buying. The very first thing to think about is dependability.

Look for a company that has been around long enough. We have huge companies that put their trust on us with their machine requirements, and still continue patronizing our products up to this moment. There’s also the parts availability, engineers, training, installation and setting up a job to consider. All of these, ITbotics and CJRTec can provide you.